KENWEI provides personalized weighing and packaging solutions for enterprises

Date:2021-07-28 16:08:56 Clicks:

Based on the company,s specific situation, Kenwei will customize a single machine or full production line to match the needed production efficiency in addition to free weighing and packaging solutions。So far, Kenwei has provided personalized customized services to more than 1500 customers in more than 90 countries and regions around the world, and continuously improved their production efficiency and economic efficiency.

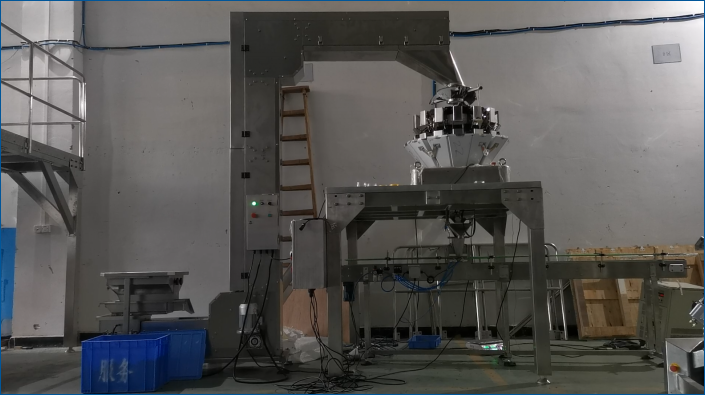

Case 1

When: November 2019.

Country: United States.

Customer requirements: the customer needed to weigh cannabis with a packaging speed of 30 packs/minute, an accuracy of 0.2g, and a weight of 2.5-5g/pack.

Solutions:

1. Based on the customer’s requirements, we offered a complete production line, including a Z-shaped bucket elevator, a 14 head multihead weigher, a working platform and a horizontal conveying line.

2. To satisfy the high accuracy requirements, we configured a high-precision 14 head multihead weigher with an accuracy of ±0.2g. The picture shown below is the final solution Kenwei provided the customer.

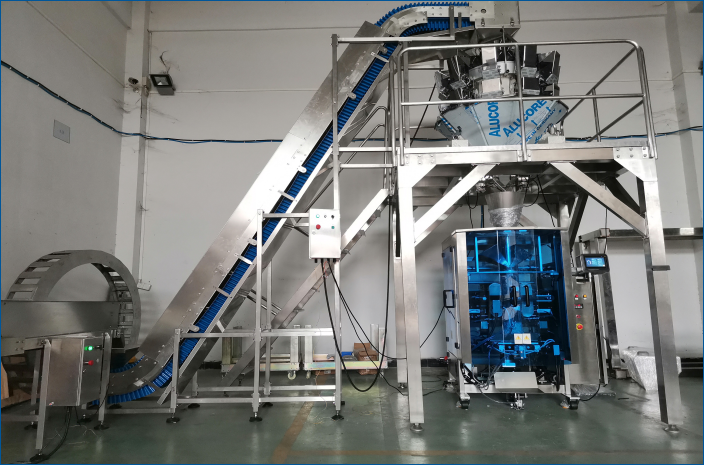

Case 2

When: October 2019.

Country: Portugal.

Customer requirements: The client needed to weigh 1kg of screws with a weighing speed of 20 packs/minute.

Solutions:

1. Kenwei customized a complete weighing and packaging system integrating a horizontal conveyor system, inclined conveyor, a 10 head multihead weigher for small hardware, working platform and VFFS packaging machine. The weighing speed is 20 bags/min.

2. A 10 head multihead weigher features a stronger impact resistance, preventing the nails from scratching the machine during the weighing and packing process. The picture shown below is the provided weighing and packaging line.

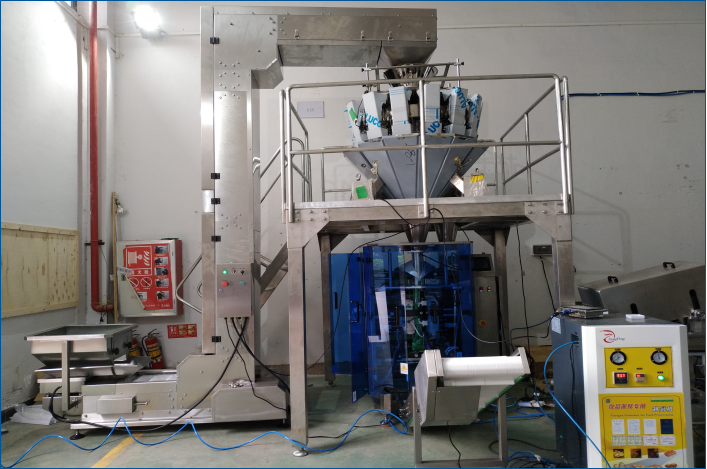

Case 3

When: October 2019.

Country: United States.

Customer requirements: The customer needed to weigh soft sweets with a weight of 100-800g/bag, a speed of 30-40 bags/minute, and an accuracy of 1-2g.

Solutions:

Following the customer’s requirements, we customized a Z-shaped bucket elevator, JW-A10-1-12 10 heads multihead weigher, working platform and horizontal conveyor system. An adhesion problem was effectively controlled.

Because soft sweets are generally soft and fluffy, an uneven feeding causes the products to take up space that does not match the labeled weight on the package. To prevent this, we configured the stuffing machine to place the soft sweets in bottles to meet customer weight requirements. The picture shown below is Kenwei’s solution.

Case 4

When: March 2019.

Country: Saudi Arabia.

Customer requirements: The customers needed to weigh perfume with a weight range of 5-35kg/bottle, a packaging speed of 40 bottles/minute, and an accuracy of 0.2g.

Solutions:

To meet customer requirements, we customized a complete set of weighing and packaging machinery, including a Z-shaped bucket elevator, 14 head multihead weigher, horizontal conveyor system, bottle unscrambler and capping machine. The customer was extremely satisfied with the machine, shown below.

Case 5

When: January 2019.

Country: Peru.

Customer requirements: The customer needed to weigh rice into bags of 500g/bag, a speed of 60 bags/minute and an accuracy of 1.5g.

Solutions:

Kenwei customized a complete set of packaging machinery, containing a Z-shaped bucket elevator, combination weigher, working platform, vertical form-filling-sealing equipment and finished product conveyor.

The picture below is Kenwei’s offered packaging machinery solution.

Case 6

When: January 2019.

Country: Poland.

Customer requirements: The customers needed a production line for frozen vegetable weighting and packaging with a height of no mo3m, each bag could weigh no more than 300g, and the line had to have a packaging speed of 20 bags/minute.

Solutions:

Based on the customer’s requirements, Kenwei specially designed a full weighing and production line that was 3 meters high. This line included a large-angle inclined conveyor, 14 head multi-head weighers, a Z-shaped bucket elevator and vertical form-fill-sealing packaging equipment. Features include twice feeding, a dosing of 300g and a packaging speed up to 20 bags/min.